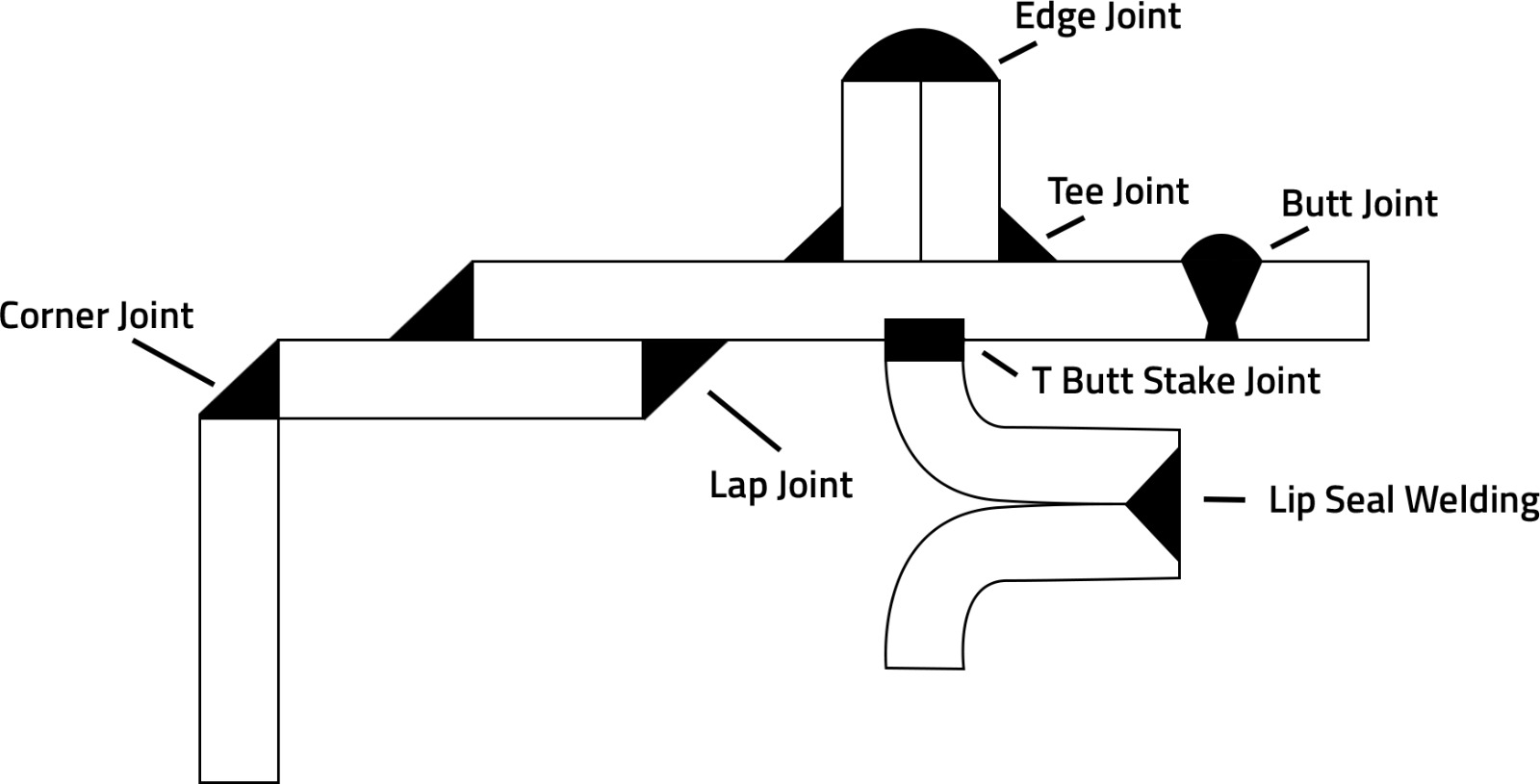

The process of jointing two or more pieces of metal as one is referred to as “Welding”. There are several conventional welding methods viz. MIG welding, TIG welding, ARC welding, spot welding and etc that are still apply by most of the factories.

WHAT IS LASER WELDING ?

Today, Laser welding is another addition to the list of welding techniques, which came into being in the early 1960s. Thanks to the extensive research in laser technology that led the scientists to identify this novel usage of laser in the metal welding industry. Instead of direct heat and pressure, a coherent beam of light photons is used to join multiple pieces of metal together as a single unit. The laser welding machines are far smaller but more efficient, powerful and economical than their previous generation counterparts. This approach allows technicians to shape metals into the desired final products which we see and use regularly.

Considering the rising necessities of the laser welding machines we reach out to you with the best ranges of machines that are supportive of combatting any sort of interruptions you may face during the welding procedure.

HOW DOES LASER WELDING WORK?

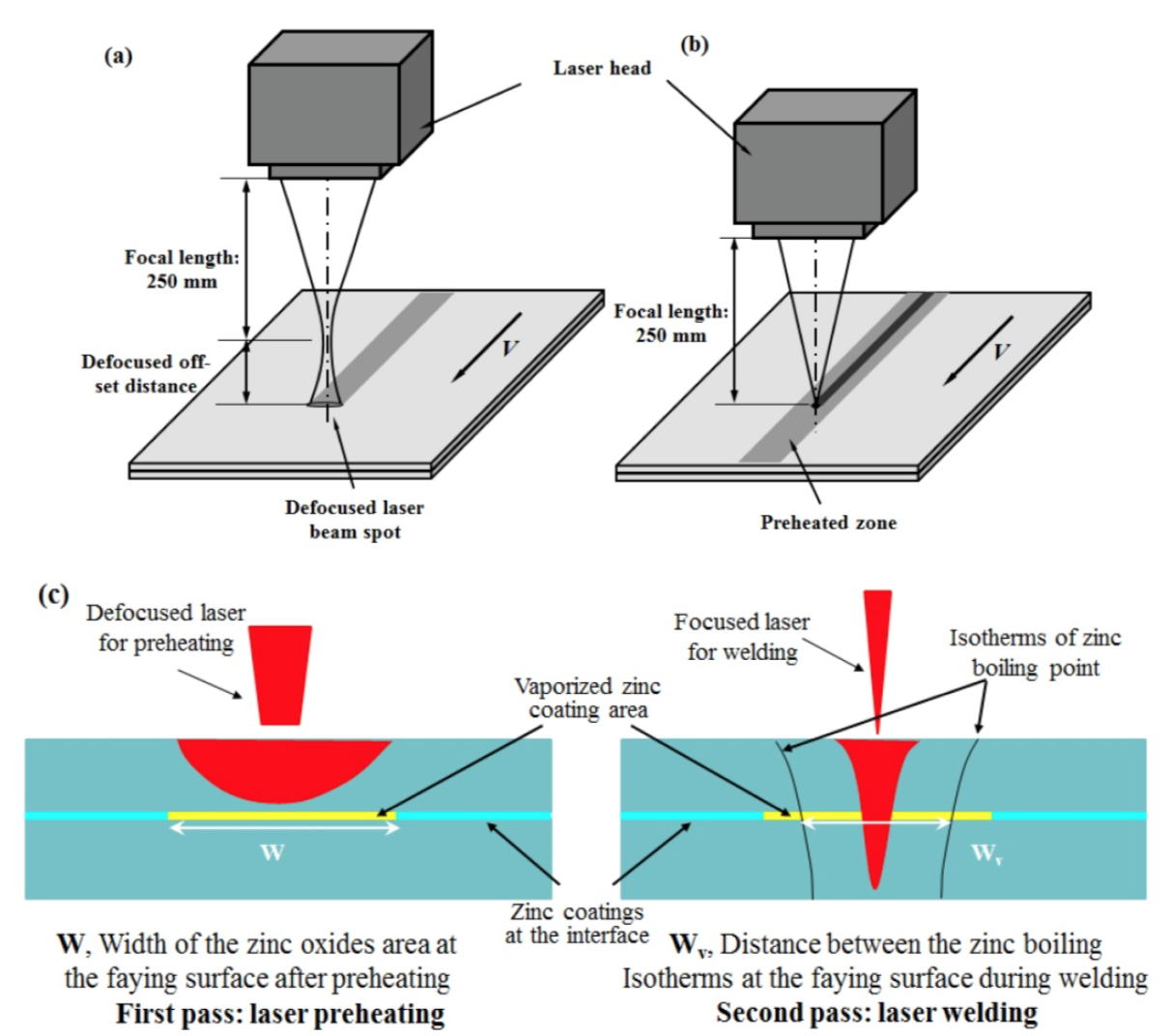

Laser welding instruments are devices which have the capability to concentrate laser photons into a high-energy beam, which produces massive heat when it comes in contact with other materials. When a thin, high powered laser beam is focussed at the juncture of two metal pieces placed over a heat resistant substrate, the resultant heat melts the metals, allowing one to mould and fuse the metal pieces into any desired shape. After the laser source is shut down, the temperature drops and solidification of liquid metals yield a single welded block of metal. Since the use of laser generates heat in a tiny area only, its permits extreme precision in welding and shaping work.

The laser beams used for welding can be charged as a continuous linear stream of photons or as a series of pulses, each lasting for a few milliseconds. While the continuous streams are utilized in making deep welds, the pulsating photons find application in cutting metals to minute pieces. In modern times, workers safety is the prime concern in industries, most welding setups make use of robotic arms to shoot the laser beam through target metals, thereby jointing them into one. Also, there are other setups where remote consoles are utilized in steering the movement of the laser beam.

There are two types of laser welding- Laser Conduction Welding and Laser Penetration Welding.

ADVANTAGES OF LASER WELDING

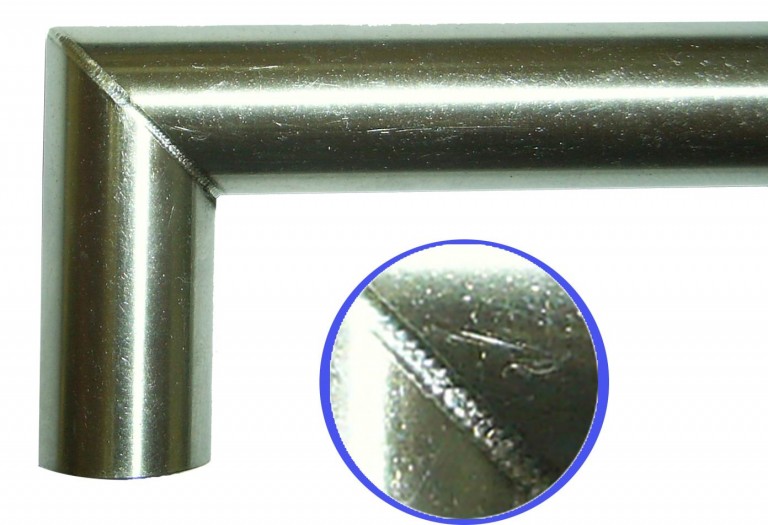

As stated earlier, laser beam welding is extremely accurate, thus it’s widely used in making of numerous precision welding products that we can see around us nowadays. This includes automobile frames, aircraft components etc. Lasers do not cause distortion on the surface of welded metals as is seen in case of other traditional techniques. The final product is so well created that it is often hard to believe that the work had actually started out with two separate pieces.

Also, the laser technique is far more versatile than its conventional counterparts. It works equally well on a wide group of metals such as aluminium, titanium, steel (carbon and stainless), nickel alloys etc. The thickness of the materials is also immaterial. Laser is powerful enough to penetrate materials of any width. Laser welding consumes much less time than other methods of welding. This feature comes handy especially while dealing with hefty blocks of metal.