|

Processing type

|

Cutting

|

| Machining radius | R1.3m-R2.0m |

|

Laser power

|

500w-2000w

|

| Positioning accuracy | ±0.1㎜/m |

|

Power supply

|

380V/50Hz

|

| Degree of freedom | 6 |

|

Rated load

|

14㎏

|

| Max. load | 28㎏ |

|

Reach of arm

|

2010㎜

|

| Repeated accuracy | ±0.05 |

|

Protection grade

|

IP65

|

Details:

Three-dimensional laser cutting machines save space and energy consumption, gas consumption Dimensional series fiber laser cutting machine of the easy maintenance, high cutting speed, cutting edge clean and smooth.

Features:

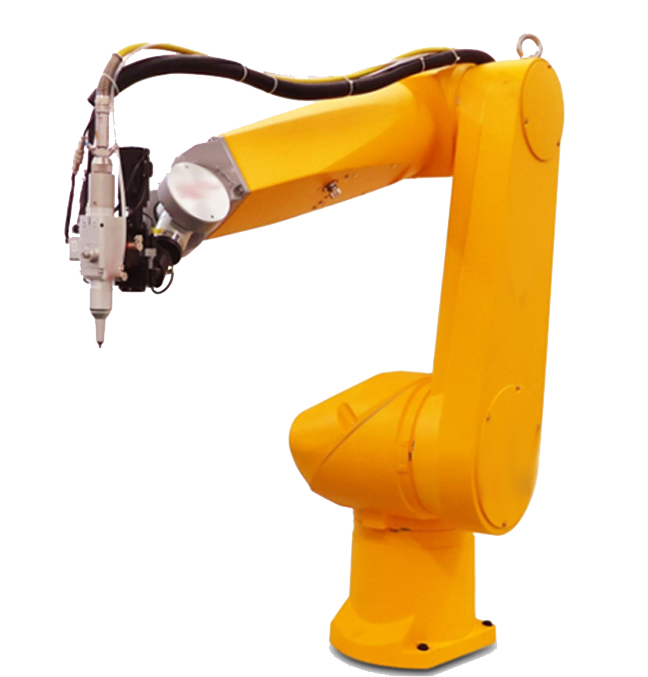

The machine is with international branded robot and six-axis control , to complete any curve movement space, to guarantee the machine's running speed, precision and reliability.

3D LASER CUTTING MACHINE

3 Dimensional Laser cutting machine is a device which is used in cutting of materials with the help of lasers. Cutting is done by directing the high power output of the laser through the lenses onto the workpiece. The laser optics and CNC is used to bring the workpiece under the focal area of the generated laser beam. The focused laser beam is directed on the material which is then melted, vaporized, burnt or blown away leaving the high quality surface finished product.

Laser cutting machine is used in industries for manufacturing. It is also used in schools, small industries and other labs for learning and other purposes. They are used to cut sheets of metals as well as piping and other structural materials in industries. A commercial laser cutter is programmed to follow a CNC which uses G-code of the patterns that is to be cut on the material using a motion control system.

Industrial cutting lasers are basically of three types based on the way the laser beam or the material is to be moved during cutting or processing. All the processes follow a three-axis coordinate system namely, X and Y for material movement and the Z axis for positioning the cutting head.

Moving material lasers allows the material to move under it where as the laser cutting head is stationary. In this machine, a constant distance with the laser generator is maintained to remove cutting effluent. Less optics is required but the workpiece has to be continuously moved. This type of laser cutter is the slowest and has less agility.

In hybrid laser, the table moves in X-axis where as the head moves in the Y-axis. It leads to more constant beam delivery and better and faster cutting. The power loss is less and the capacity of this cutter is the maximum.

Flying laser optics has a stationary table and the cutting head moves over the workpiece in all directions. They do not require metal clamping. This laser cutter is the fastest and has advantage over the others in cutting thinner jobs.

The 3D laser cutting machine uses a robotic arm manufactured by the ABB. It has higher cost benefits than the conventional five-axis laser cutters. They occupy less space and are optimized easily for the better production layout. It is accompanied with a simulation software tool that allows the user to generate the cutting program and modify it easily whenever required. It can be operated manually and has easier commanding options.

A program is fed in the machine’s CNC which is directly linked with the laser cutter. The CNC guides the laser cutter to perform its task in a way as depicted in the program. The simulation arm can reach all around the workpiece and constantly cut through the job to create the required product.

A 3D laser cutting machine is an easy to use cutting device. It has huge advantage on other cutting devices when it comes to mass production. It can cut the jobs with high accuracy at unbelievable speed. In no time the batch is produced and the lot is complete. It needs minimum maintenance and the operating cost is also very less. Once the program is fed into the CNC, the laser starts following the program and cuts the workpiece accordingly.

3D laser cutting machine is faster and accurate. It takes less time and provides better surface finish. It has very less scope of error once the correct program is fed in the system. CKY & Hymson laser cutting machines are one of the biggest and most trusted brands in the field of 3D Laser cutting machinery. They are reliable and provide better after sales service to their clients.