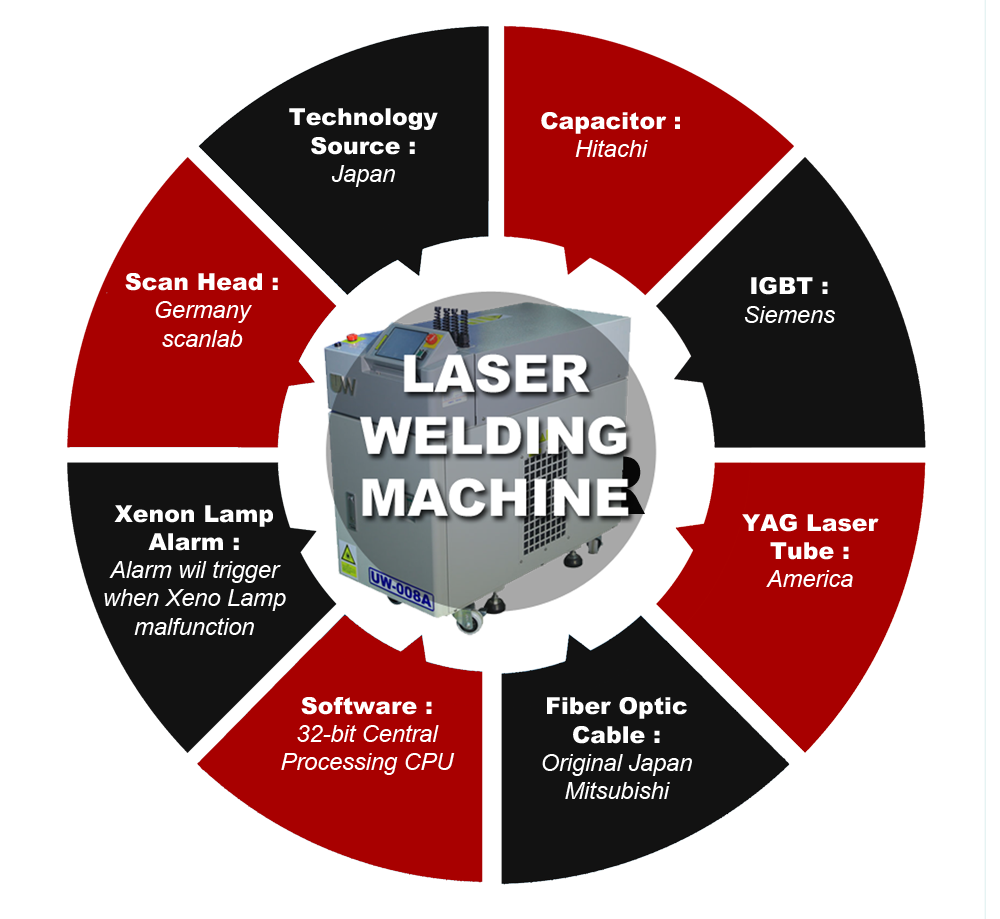

ROBOTIC LASER WELDING MACHINE

TYPES OF LASER MACHINE

BRIEF INTRODUCTION

Laser welding systems are indiscriminately used in a variety of fields (science, medicine and industries such as automotive, aerospace, electrical/electronics etc.) to efficiently and economically make high-quality joints, by eliminating the need for direct contact. These days, laser can flawlessly join both metal and plastic components. Often, laser welding is used for encapsulating electrical components like switching devices that need to be protected and sealed. Also, it is used in the manufacturing of hypodermic needles, tube assemblies, welding razor components and welding tungsten filaments used in halogen bulbs. Selecting the perfect laser welding machine to suit your needs, is not an easy job. This is a heavy investment for the user and hence, cannot be taken lightly. You need to do some homework in order to decide on the right kind of laser equipment that will serve your purpose and enhance your business. The most expensive laser machines can cost up to thousands of dollars, but you don’t necessarily need to spend that much. With significant research, you can narrow down the essential features that need to be present in your machine and this reduces unnecessary burden on your business.

- Handheld

- Light Weight

- Wobble

- Single Wire Feeding

- Handheld

- Light Weight

- Wobble

- Single & Double Wire Feeding

- Robotic/Automation

- Light Weight

- Wobble

- Wire Feeding

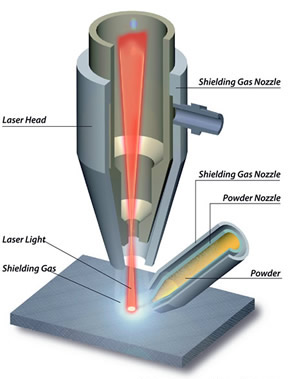

- Robotic/Automation

- Scanner

- Spot Welding

FIBER

Fiber laser welding machines have higher power output of approximately 10 KW. The laser beams generated here have high consistency and consume significantly less time in welding thick materials including exotic alloys. However, there is no spot function. All through, there is high power generation and this can be used to yield thin cuts, etches and welds.