LASER SOLDERING MACHINE

Laser soldering machine is used to solder and braze metal strips with the help of laser diodes which focuses the laser beam and provides controlled heating of the alloy to be soldered to make a fast and non-destructive joint. The machine uses a controlled laser beam to transfer heat energy to the soldering point where the absorbed energy is used to heat the solder until it reaches the melting temperature. In laser soldering machine, there is absolutely no mechanical contact which makes it pure joint.

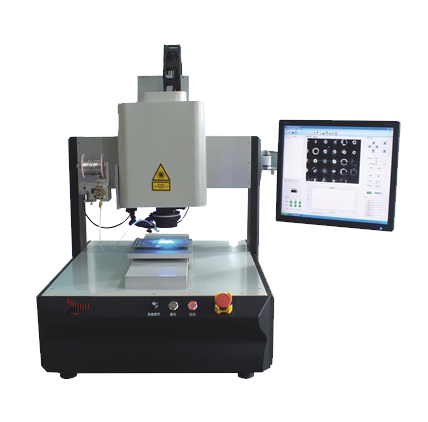

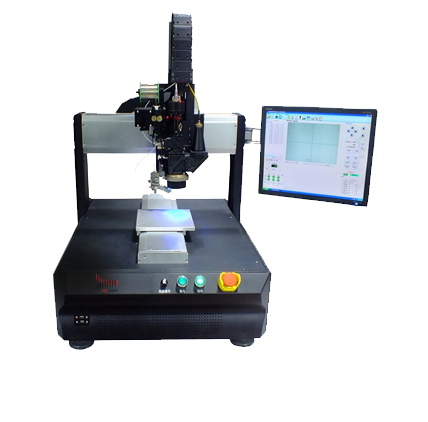

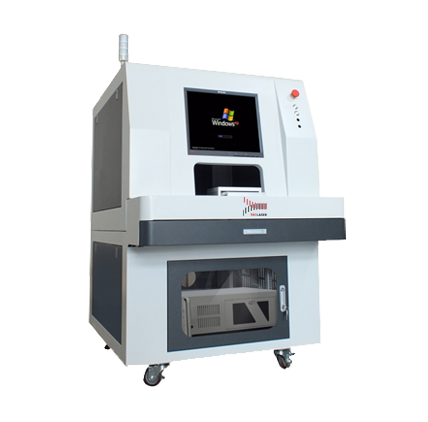

The laser soldering machine consists of a laser generator, focusing optics, fiber optics module, illuminator with motion module, computer vision module with an in-built camera and the X-Y positioning stage with servo control system. The laser diode generates the laser beam and modulates it. The optical system helps the laser beam to focus accurately on to the workpiece’s solder joint.

The temperature at the solder joint is generated by the absorption of the heat irradiation. The energy can be controlled precisely and is beneficial for reflow soldering with solder wire as well as soldering paste. The output is delivered to the solder area with the help of input coupling optics mounted on adjustable mounter fiber optics module, a connectorized fiber cable and output coupling optics.

The device is placed in the position by a servo operated XY table which is responsible for accurately positioning and moving the workpiece under the fixed laser beam. The galvanometers, that are the computer controlled positioning mirrors takes care of the movement of the laser spot on surface mount device. These mirrors are used to control the laser path and are programmed for each component type and these are stored in the computer interface.

The high level of automation of the machine results in continuous process. To increase the stability, a closed loop temperature control is controlled with the help of a pyrometer. The pyrometer continuously monitors the temperature and this ensures repeatable and reliable process. Whenever there is change in temperature, the pyrometer sends a feedback and the laser regulates the temperature again.

The laser soldering machine has a lot of advantages over other conventional machines and processes. It is contactless and has locally limited application of energy. It makes the soldering pure and free from impurities. The laser provides temporally and spatially well-controlled uniform energy input. Very less thermal stress is developed in laser soldering. It reduces the formation of intermetallic compounds because of the rapid joint formation resulting in the formation of high quality joint. The laser requires very low maintenance and is very flexible and easily adaptable. Laser soldering leads to fine grain size and it results in improved fatigue properties.