STAINLESS STEEL

ALUMINUM

COPPER

GALVANISED STEEL

METAL SHEET

CARBON STEEL

ALLOY STEEL

TITANIUM

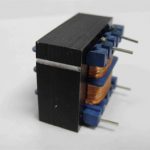

ELECTRONIC COMPONENTS

SAMPLE NAME

SAMPLE NAME

SAMPLE NAME

SAMPLE NAME

SAMPLE NAME

SAMPLE NAME

SAMPLE NAME

APPLICATION OF

LASER WELDING

LASER stands for Light Amplification by Stimulated Emission of Radiation and refers to a thin monochromatic and coherent beam of high intensity energy. Since its discovery in the early 1960s, it has quickly marked its way out of the academic lab into the factory floor, where it is being used in various fields. Laser finds application in non-invasive medical surgeries, sophisticated laser-sight enabled rifles, laser computer printers, office photocopiers, motion sensors, locking and unlocking car doors, satellite signalling and dozens of other areas. As technology is progressing, improved lasers are working their way into even more aspects of life around us, including the welding industry. Laser is capable of generating massive amount of heat that melts metals, when it hits against its surface. This forms the principle behind its utilization in the welding process.

Laser welding is now commonly used alongside other conventional modes of welding such as MIG, TIG, ARC etc. The advantages of using this technology over the traditional counterparts’ are- its acute precision in the place of application, its versatility in terms of the range of metals on which it can be used, its huge penetrative power and reduced time for yielding the desired outcome. Besides being used for jointing normal sized pieces of metals as found in consumer electronics, automobile, aircraft and spacecraft, laser is also suitable for micro welds which lies outside the scope of the age-old welding methods. It is used in making of the complex light-weight parts in computers, jewellery manufacturing and engraving, in dentistry, tool and die industry etc. Laser etching and welding is a very convenient, low-cost and highly efficient method for manufacturers to produce these parts.

In the field of automobile, aircraft and spacecraft manufacturing, laser welding has been duly embraced because of its flexibility in augmenting parts, while still aiding in maintaining the consistency for mass production. Use of laser lowers the overall demand of equipments in the factory’s work facility, thereby making the entire process very economical as opposed to the stamping method of welding. With the upcoming demand of reducing carrier weight for improving fuel efficiency, more and more manufacturers are opting for laser manufacturing because the component parts can be easily engineered using thinner dimensions of lighter weight metals such as aluminium. Use of laser eliminates distortions in thin-gauge metals and also eliminates the need for a filler metal between the riveted parts, once again dropping the weight of the aircraft by another five percent. This type of welding also makes the carrier less susceptible to corrosion by air friction and hence drives down maintenance costs in the future. Using laser is a very eco-friendly option in manufacturing because it helps to cut down on the facility’s total CO2 emission, thus making it easier to meet global CO2 emission standards. Other applications that laser serves in the automotive industry include brazing and soldering of surface components, welding powertrain components of the engine, development of fuel cells and batteries. Undoubtedly, there is no modern vehicle on the street that has not used laser in manufacturing of at least some of its parts.

Laser can be used innovatively and flexibly in polishing, hardening, drilling, marking, imprinting, engraving, pinpoint welding and precision cutting for laser surface engraving or micromachining, done with the purpose of improving various products. Here, laser not only manipulates focused light beams to cut through rigid materials but also uses certain substances in gathering electromagnetic power for use in different engraving procedures. Laser Engraving has different applications e.g. processing of different materials like rubbers and different polymers, laser cutting of different metals such as stainless steel, aluminium, copper sheets, silicon sheets, nickel plates etc., laser drilling of tubes, needles, injection tools and much more.