A. SERIES OF FIBER

Laser Cutting Machine

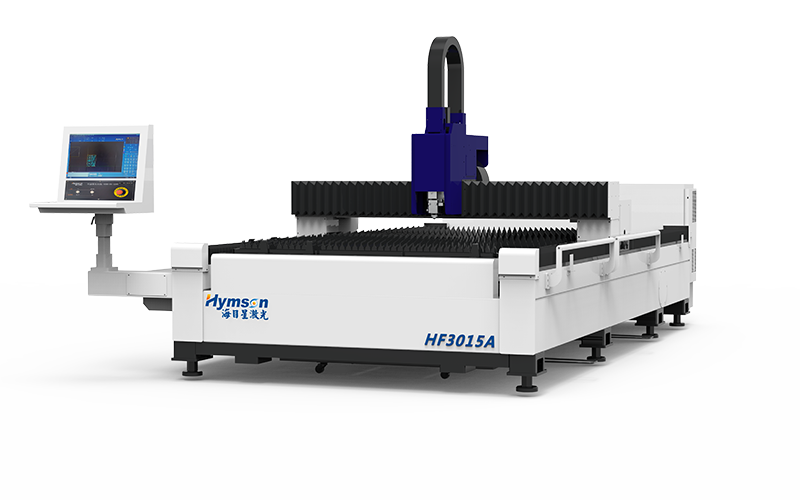

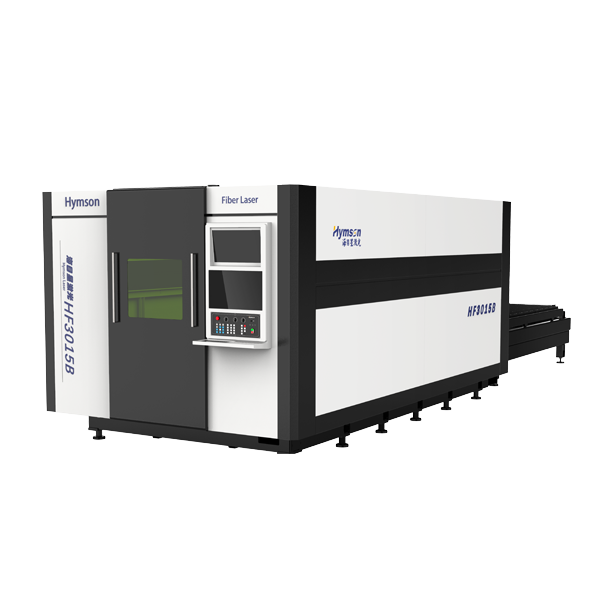

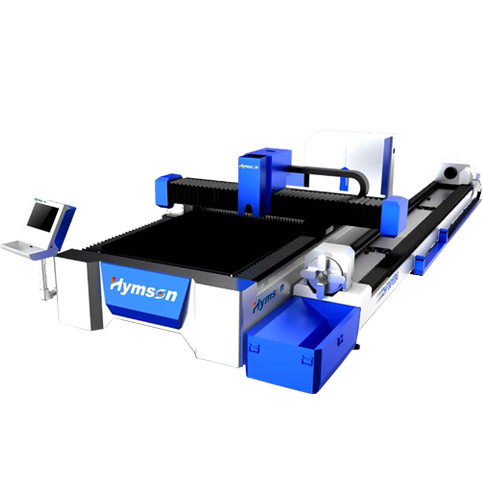

Manual laoding, easier operate and flexible machining, lower maintenance requirements.

Manual laoding, easier operate and flexible machining, lower maintenance requirements.

High cutting efficiency, high cost performance and low running cost.

High cutting performance for copper/brass, aluminium, stainless steel and carbon steel.

Workable for sheets and pipes.

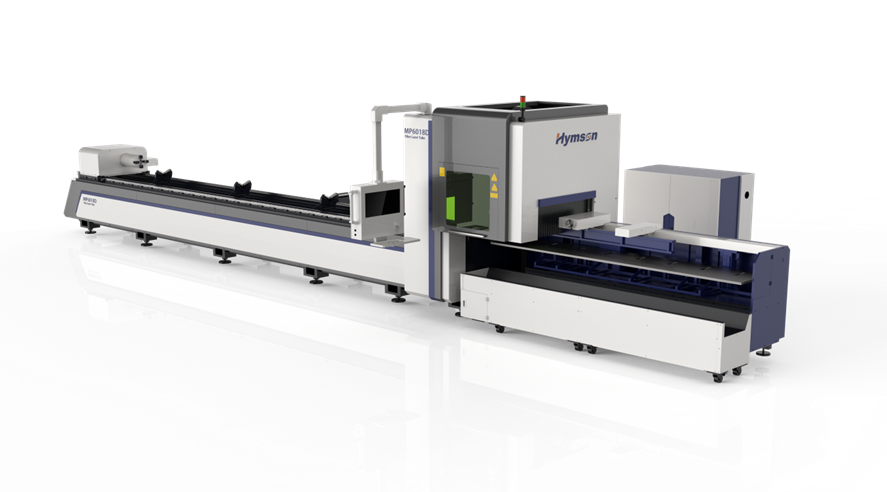

Pipe cutting only.

Flexible design for customized requirement.

Pipe cutting diameter Max ⌀ 500 MM.

Fast investment return.

Tecxin is a leading e-commerce site that deals specifically in selling high quality welding, soldering and cutting machines from a variety of esteemed and reputed sellers from the world. Our trusted and reliable services have made us into the leading name in machines providing community hence we have been awarded distributorship from global brands for south Asian markets mainly Malaysia. For your machining business to work efficiently you need to have good cutting, welding and other machineries and our website provides you with the best. This post makes it clear to you, why fiber laser cutting machines are one of the most probable kinds you should go for and why are they the best choice.

A fiber laser is one in which the active gain medium is an optical fiber which is doped with rare-earth elements such as ytterbium, neodymium, erbium, praseodymium and a few others. These are in relation to doped fiber amplifiers that give light amplification without lasing. Fiber nonlinearities or four-wave mixing can also provide gain and consequently serve as a gain media.

The laser cavity is made monolithically by fusion splicing. Many high-power fiber lasers are based on double-clad fiber. The gain medium becomes the core, surrounded by cladding. The core is pumped with much higher power beam. The design is made such that it allows the core to be small enough to support only a few modes. It should provide enough cladding to confine optical pump section and core over a relatively short fiber piece. They are mainly available in two configurations :- Q-switched or MOPA.

High power fiber laser cutting machine makes use of semiconductor diodes in the pumping mechanism and a doped fiber optic cable as gain medium. In this, doped fiber optic behaves as the resonator.

Fiber Laser Cutting material metal processing aluminium, carbon steel, stainless steel, alloy steel copper, titanium & etc.

The main advantages that highlight the quality of fiber laser are-

Fiber lasers, due to their compact, thin and finely made design, do not lose much of their energy. Also, as mentioned above, they module life in fiber laser have the longest possible life till date. Extending to almost a 100,000 hours, they serve as a one-time investment. We, at TECXIN provide you with the best quality of fiber laser cutting machine in Malaysia from esteemed companies like TEC Laser . From the initial contact going through the installations of your laser system and beyond, we aim at providing a personalized consultative approach for solving your problems. Do approach our site and obtain a friendly and easy purchase experience.