CUSTOMIZE JIGS & FIXTURES

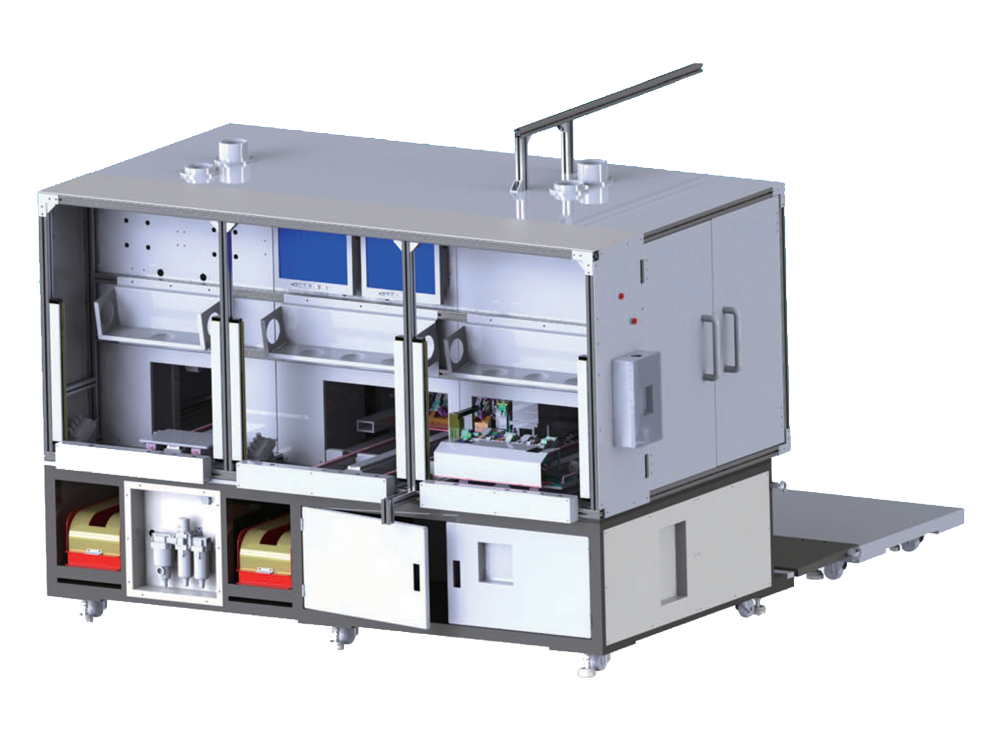

Laser machines are the devices which are used to perform a variety of tasks on a variety of designs and modules. These machines are suitable to perform tasks on any sort of design and shapes. Not all shapes and sizes can be handled on the in-built table frame of the laser machine. Sometimes, when there is need to work on non-geometric or complex geometric shaped workpieces, additional support and clamping is required for making the precise cuts.

The laser cutting table system which is generally designed to help the operator clamp down the usual shaped jobs have literally no option to clamp the unusual shaped objects. The jigs and fixtures are then customized to fit a specific job and perform the task which was otherwise not possible because of inadequate clamping. The customized fixtures are used for writing utensils, coffee mugs, lapel pins, pocket knives, glassware, identification tags and key chains.

These jigs and fixtures assist the user to use the table efficiently and setup the rack system on v blocks. The innovative modular system is convenient for all types of laser beds. The fixtures optimize the productivity during mass production or multi-production. The jigs help in worriless and consistent product levelling and placement for precise lasing action every time.