OVERVIEW OF

FIBER LASER WELDING MACHINES

Laser welding is a type of welding technology that is used to join several metal parts together. The main advantage of laser is that it produces high intensity of photon beams concentrated to one spot. This method helps getting fine,deep welds done a higher rate. But with the advancement of technology and higher consumption rates for the industries we need machines that can offer better results at lower inputs. Higher precision control along with low electrical energy consumption and low heat input is what the industries are demanding in order to increase their production rate at a comparatively lower rates. Continuous Wave Fiber Laser Welding is that advancement in the technology that offers all of the above.

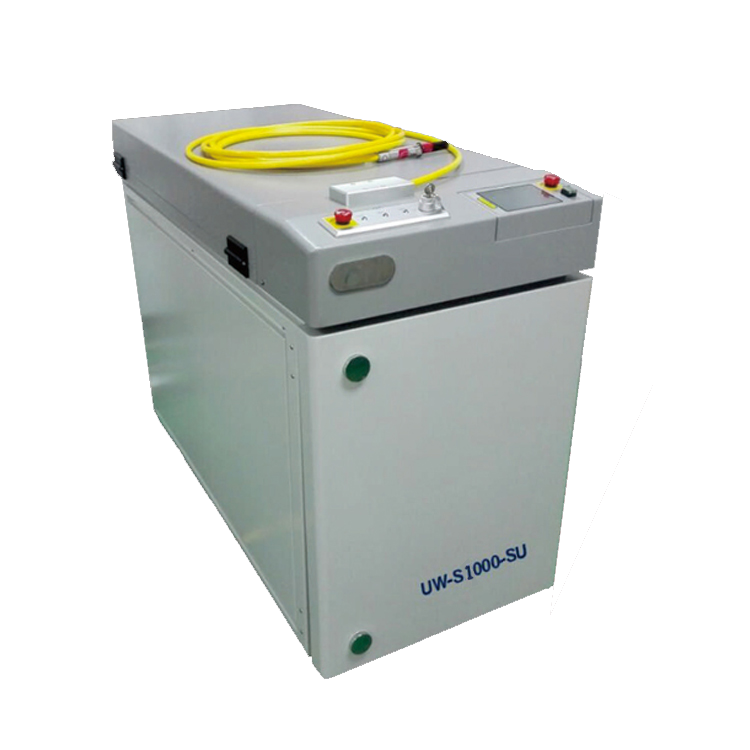

In the fiber laser the laser light is produced in an active fiber and guided to the spot to be welded by a delivery fiber. The flexibility of deliveries offers a great deal of convenience to the tough spots and is hugely favorable for processes like laser cutting,laser welding laser engraving and even laser marking.

ADVANTAGES OF

FIBER LASER VS CONVENTIONAL WELDING MACHINES

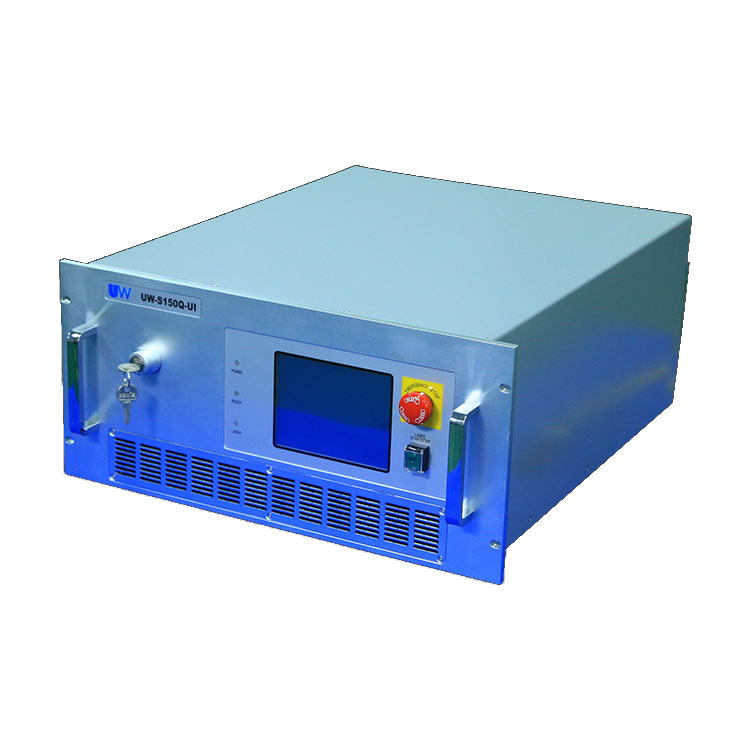

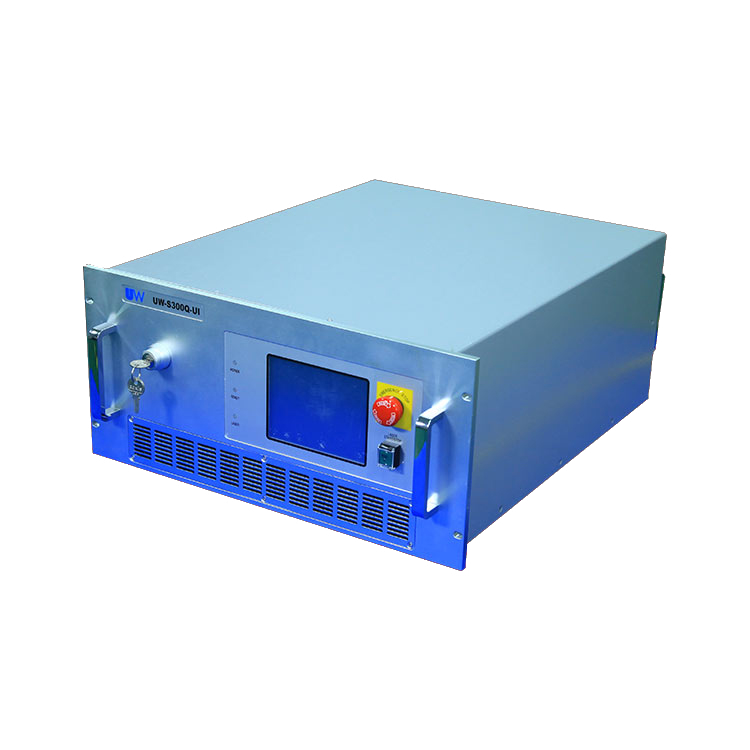

Fiber Laser Welding offers a great deal of advantages over the other conventional methods of welding. They come in both continuous wave(CW) and pulsed. As the name describes in CW fiber laser technique an uninterrupted flow is experienced and thus resulting in a greater output. Fiber lasers are practically a better option of saving money in the long run. The maintenance cost of these are inherently zero as the laser components are built into a fiber optic. Realignment requirement is met with this thus saving a lot of money.

Smaller in size and complete package makes it easier to use. The need for an external power supply is met well and being smaller in size it can be placed close to the work piece thus providing better results. Best option for robot based applications as delivery fibers makes it easier to use on the complicated places. Can be used in highly dynamic applications this is a way better option.

The efficiency of a fiber welding machine records at a 25% plus hike than the conventional welding machines. Highly economical and greater coupling efficiency makes it more popular in the industries. The fiber laser also comes in a range of power options thus providing you with the proper requirements of yours. High power to low power are available in the market making it easy to choose and invest according to your needs.

THE APPLICATION OF

FIBER LASER WELDING

The applications of Fiber Laser Welding machines(CW and Pulse Fiber Engine Output) has witnessed a great amount of hike in the recent times. To meet the needs of today’s advancement in technology Fiber Laser Welders are the best option in many fields. Greatly used in the medicine markets to make medical devices and components and also in the aerospace and electronics markets. Fiber Laser Welding Machines are also widely used in making automotive and micro components. These industries have seen a great amount of profit with the introduction of these machine in the market as the features and advantages these offer are better.