Optical requirements

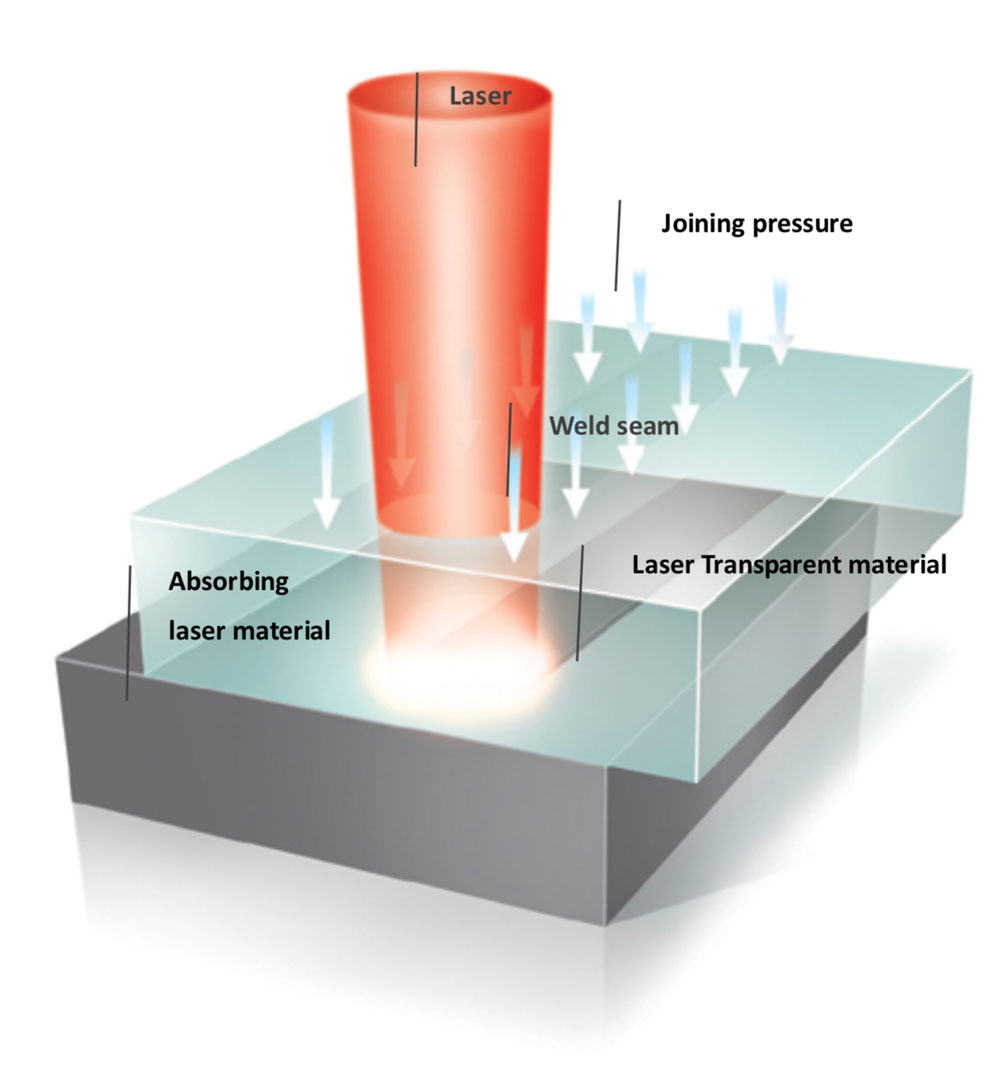

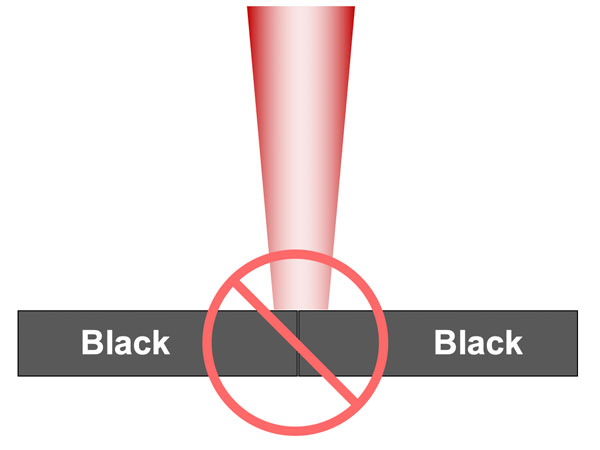

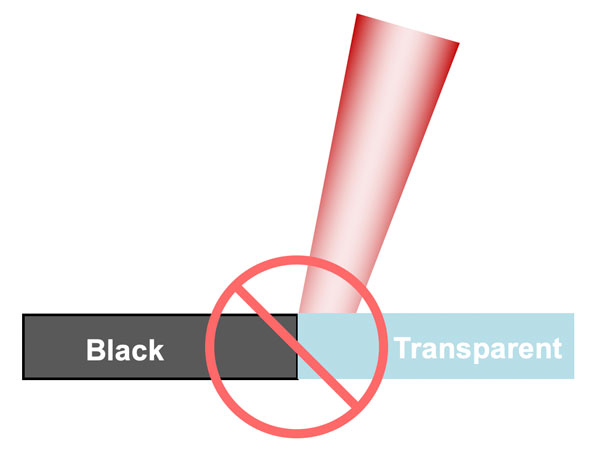

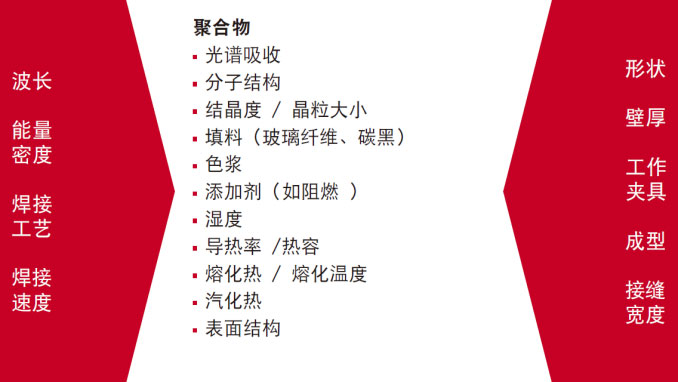

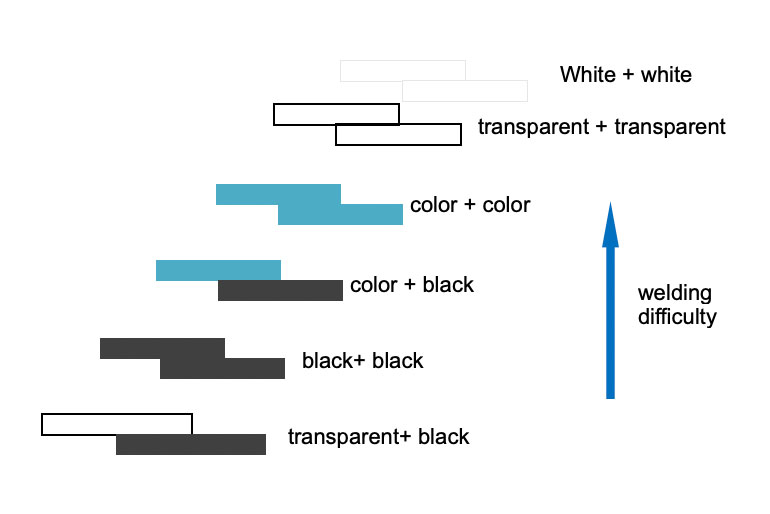

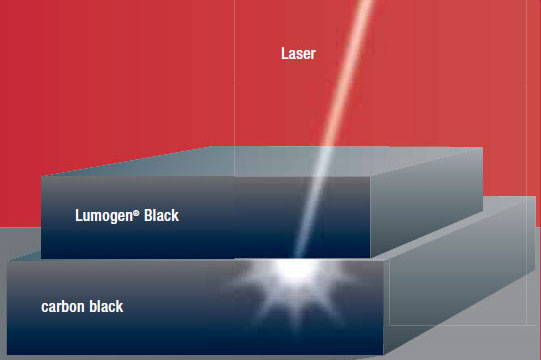

Plastic laser welding requires a combination of laser transmission material and laser absorption material. In the natural conditions, the general thermoplastic material is transparent to the laser, but the absorbent effect can be achieved by an additive (e.g., carbon black).

“Laser Transparency” is different from “Optical Transparency”, the laser wavelength belongs to the laser spectrum that human eye is not visible. In fact, many plastic laser welding applications only need the upper layer transparent to the laser. As a result, some materials that transparent under the laser but heavy color under the human eye are developed for plastic laser welding.

Material thickness, crystal properties, glass fiber content, other additives (such as flame retardants) may affect the laser transmission effect of the material. Generally need to ensure that more than 20% of the laser energy through the upper layer absorbed by the lower layer to obtain a good welding effect. Low laser transmission effect will make the upper layer first decomposition during the process of welding.—— UW has the professional measurement equipment to complete the material’s laser transmission test.

For the bottom layer absorption effect, the main way is to add carbon black, and other additives have less influence on the bottom absorption effect.