WHAT IS

YAG LASER WELDING

The procedure of jointing metal parts side by side or over each other is what we understand by the term “Welding”. Number of procedures and techniques have evolved over time and the old ways are being replaced everyday by latest techniques making more promising effects in the industries. Laser Beam Welding (LBW) technique is what is ruling the industry right now. This technique involves joining of metal parts by the means of a laser. High concentrated heat beam making deep,narrow and high rates of welding. The LBW techniques are incorporated in the fields where high volume of welds are done on a large scale like in automotive industry. Totally based on keyhole and penetration mode welding this method of welding offers high precision and great returns. LBW is a better option over EBW and are greatly gaining the popularity.

YAG lasers or yttrium aluminum garnet lasers is classified under solid-state lasers beside ruby lasers.

The solid state lasers has a great advantage over gas lasers as they operates at wavelengths at a order of 1 micrometer which is much shorter than gas lasers. The YAG lasers can work on both pulsed and continuous mode where as the other forms are only limited to pulsed modes.

MARKET USAGE OF

YAG LASER WELDING

YAG lasers are used in the electronics,medical fine mechanics and greatly in the automotive markets. The applications and the usage includes

- Welding of stainless steel,alloy of aluminum and other different softer metals.

- Electron guns and titanium capacitors also use YAG laser welding techniques.

- Spot welding of optical fibre parts.

- Containers are also welded by this technique.

- Lithium batteries are sealed by this application.

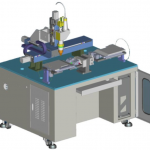

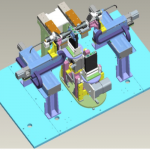

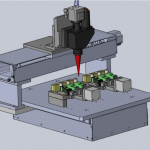

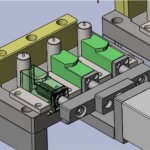

MAIN COMPONENTS OF

YAG LASER WELDING MACHINE

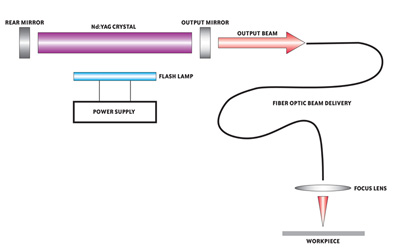

The main components of YAG laser welders include many small part and complicated machinery confined to a very small space. The main component being the YAG laser rod and others include laser diodes and the rest. The YAG lasers are optically pumped using the laser diodes or the flashtube. Use of an optical switch in the laser cavity is used to reach the maximum population inversion. Thus providing you with maximum efficiency and results.

ADVANTAGES OF

YAG LASER WELDING

There are many reasons why people and companies are using the solid state laser welding techniques,primarily the YAG lasers for their industry based works they are hugely more cost effective offering a great amount returns for a lower cost. YAG lasers works well with high alloy metals without difficulty giving you the authority to work in the open air. Extremely accurate and also narrow heat affected zones gives it ab better usage option. They even produce deep and narrow welds with low distortion rates and high quality welds and these can even weld the smallest of components.

SAFETY PRECAUTION WORKING WITH

YAG LASER WELDERS

There are number of safety issues at stake while one uses the YAG laser welding methods. As these are hugely concentrated and lasers being highly penetrative, one needs to have proper safety techniques to work. Knowing about the risks and the safety procedures reduces the risk of damage by a large amount. Proper equipment is required to work in this atmosphere.